In the uncanny upheaval of the so-called green, sustainable, and energy-efficient design, something paradoxical is happening—the architect of today, similarly to the user of architecture, is gradually losing sense of what architecture is composed of and how. So much so that tragically and often without knowing, people end up living in homes and environments that are slowly poisoning them.

Guided by the leftovers of engineered wood that we found at the Vares architecture residency in Valga, Estonia, we ventured to go after sketchy materials. We traced the bigger processes that are connected to the production of engineered wood. These materials are produced from industry leftovers, but also from trees that are cut for that purpose only. The naive idea of Max Himmelheber, the inventor who patented the particleboard, that the material would be produced from wood leftovers is far from today’s reality.1

The wood industry plays a big role in the Baltic countries. Lithuania, for example, is the second biggest European wood supplier for IKEA which produces most of its furniture from engineered wood.2 VMG Group, the biggest producer of engineered wood products in Lithuania, which manufactures particleboards, OSB, MDF, LVL, and wood chips, exports more than 90% of its products to Scandinavia, North America, Australia, and major EU markets.3 One of the biggest engineered wood manufacturers in Latvia, Kronospan Riga of the Kronospan Group, has 41 manufacturing bases all over the EU and exports 97% of its products. It has been found that multiple Kronospan production sites are releasing formaldehyde-polluted wastewater as well as polluting the air.4 Engineered wood, which is often presented as a sustainable, low-carbon alternative to more CO2-intensive construction materials, involves cutting down forests to make ‘fake’ wood; its production contaminates the environment further, and the products themselves contain toxic chemicals that add to the toxic waste piles when they biodegrade—engineered wood products are bonded with strong resins that evaporate over time. Newly-produced engineered wood boards, especially the uncoated ones, can release high amounts of formaldehyde, a known carcinogen.

Having dived into the dense layers of glued wood and spent an extended time looking into the leftovers piled up at the residency, we took up a challenging experiment of organising, assembling, and disassembling. We had to find a way to work with the sketchy materials, raising the question of how to reuse them. The process led to constructing ‘sketchy objects’—vibrant mosaics and stools made of the sketchy scraps and bound together with natural jute rope. After all, even the sketchy particleboards are not completely hopeless—they can still be an ecological material if they have been produced fully from leftover wood and bonded with natural resins that do not emit toxic fumes.

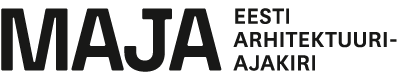

Particleboard

This suspicious actor is also referred to as chipboard. Nowadays the boards are produced mostly from newly cut trees, with tree plantations grown solely for that purpose. Particleboard is composed of ∼80% wood, 9–10% urea-formaldehyde glue, 7–10% water and less than 0.5% paraffin.

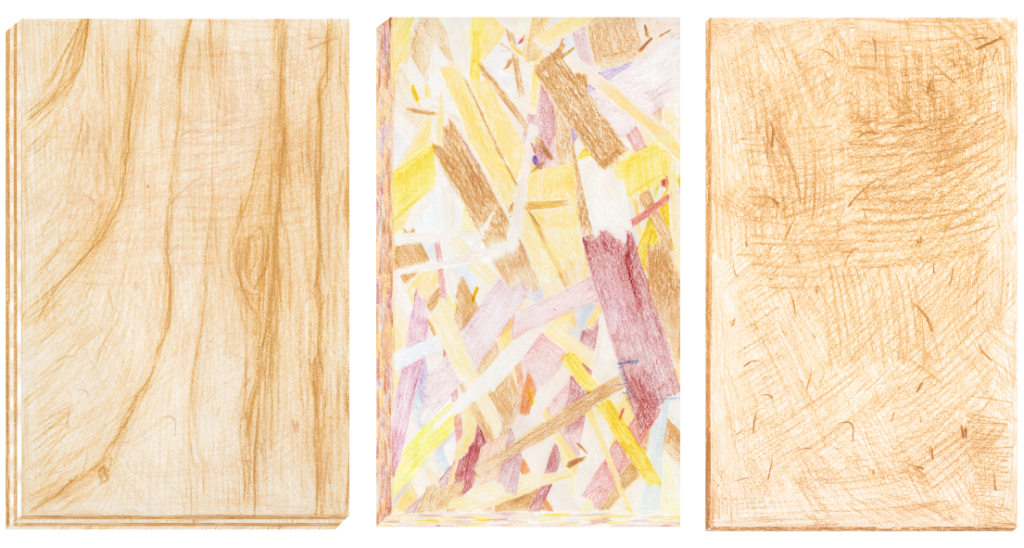

Oriented Strand Board (OSB)

Its unique look directly points to its specialty—strands of wood are layered together in different directions. In the outer layers, the strands are oriented longitudinally in line with the panel length, whereas in the middle layers, the strands are smaller and lie crosswise. OSB is usually composed of 90% wood strands, phenol-formaldehyde (PF), melamine-fortified urea-formaldehyde (MUF) or isocyanate (PMDI).

High Density Fibreboard (HDF)

This composite material is a type of fibreboard that has the quality of being particularly thin and dense, with a smooth, homogenous surface. The hardboard is usually composed of 97% hardwood sawdust, paraffin wax, linseed oil, and polymers. Depending on its production method, HDF may also contain urea-formaldehyde or phenol-formaldehyde.

Medium Density Fibreboard (MDF)

This material is a man-made wood that is composed of pulverised wood fibres mixed with resins and wax, before being pressed into flat panels under high temperatures and pressure. Formaldehyde resins are commonly used to bond the fibres. MDF is usually composed of 82% wood fibre, urea-formaldehyde resin glue, water, and paraffin wax.

Plywood

Plywood veneers are bonded under pressure in high heat and using strong adhesives. Ancient prototypes of plywood were glued together using natural glue made from animal-sourced gelatine—from bone, skin, tendons, and cartilage. Plywood is usually composed of hardwood or softwood veneers and phenol-formaldehyde, though urea-formaldehyde or melamine-formaldehyde can also be used.

Cross Laminated Timber (CLT)

CLT is produced from industrially dried, quick-growing softwood boards stacked perpendicularly and glued together in multiple layers. CLT is composed of at least three layers of wood (usually three, five, seven or nine), glued together with strong resins such as polyurethane (PUR), melamine-urea-formaldehyde (MUR), and melamine-formaldehyde (MF) and resorcinol-based resins.

Instructions of use

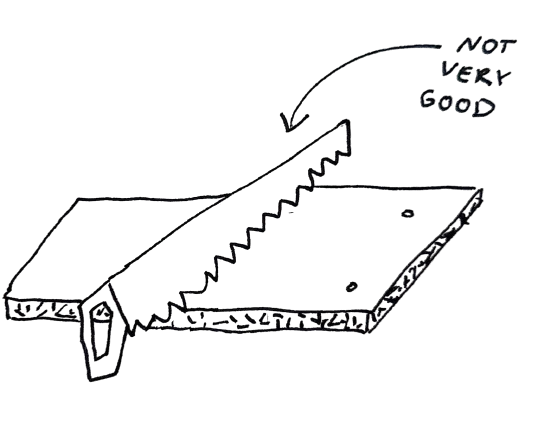

Before working with sketchy materials pretending to be wood, consider using the pieces as they are as well as using non-invasive binding methods. When a piece is damaged, the chemicals stored in the resin are released.

Try to avoid cutting, drilling or glueing the materials; only do it if it is really necessary.

Open the windows and let some air in! Make sure that the workspace as well as the storage site of the materials are well-ventilated.

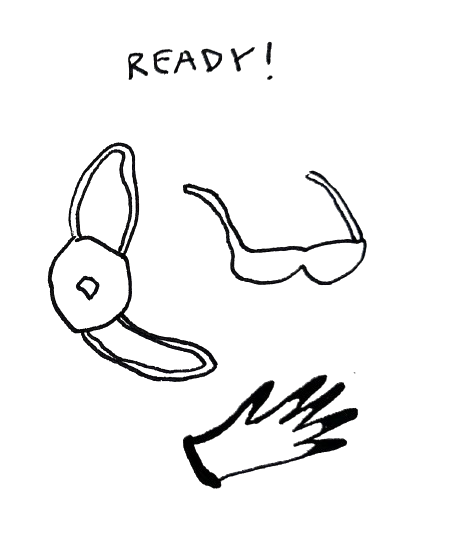

If you are cutting, use a face mask, glasses, and gloves. It is best to do it outside.

Keep the toxic stuff from escaping. Painting or covering the chipboards (not laminated ones) with a layer of natural paint or varnish may reduce chemical emissions. Wear a mask while doing so.

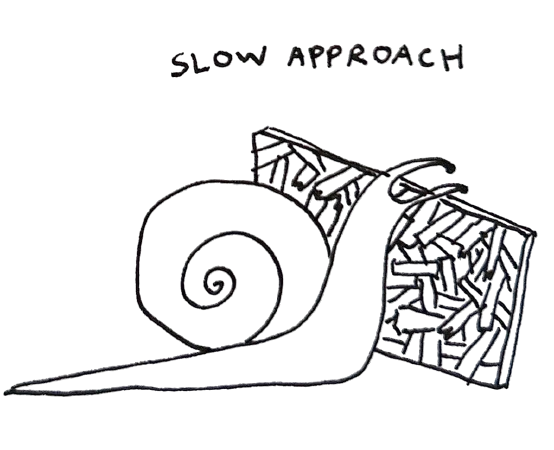

Keep it slow. Take your time to get to know the materials. By organising and paying attention, you may get inspired by some cracks or holes or nooks and see these materials in a new light. You might embark on an artistic adventure that is mindful of the materials’ sketchiness and therefore more sustainable.

Wash your hands well after touching glued wood, as the chemicals might irritate the skin.

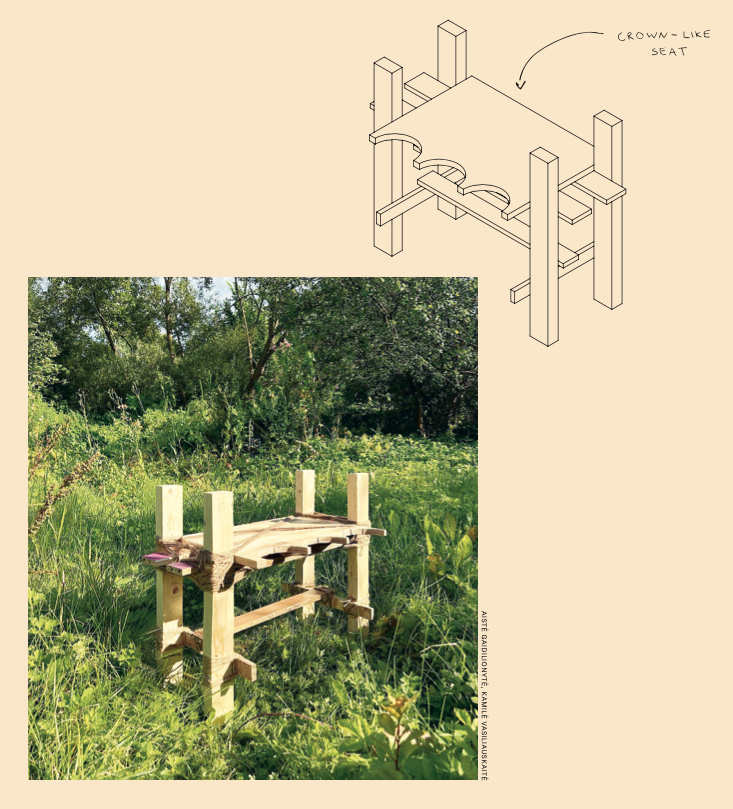

The Royal One

This stool, or should we say throne, is composed of carefully selected and almost perfectly matching pieces found among the leftovers of glued wood at Vares. It is comfortably firm and of generous height and width. Following an ancient technique, a rope holds together the parts of the seating platform and tightly connects it to the four legs. This one might be squeaky when you first sit on it but worry not—it holds very well.

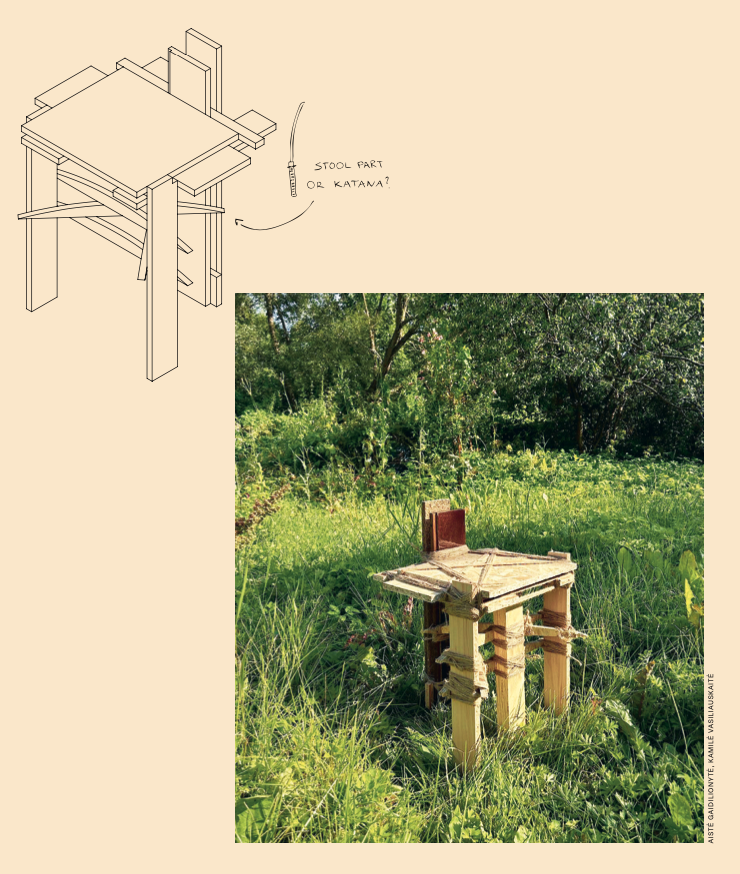

The Samurai One

The plastic and eclectic look of this stool is due to the assembly of small pieces of glued wood leftovers. By coming up with ways to tie the petite parts together, it was possible to achieve a higher level of detail in an object. The tiny sharp elements between the chairlegs may even resemble elaborate samurai swords.

Sketchy terms

- Formaldehyde is a colourless, strong-smelling, flammable chemical that is produced industrially and used in building materials such as particleboard, plywood, and other pressed wood products. It is commonly used as a fungicide, germicide, and disinfectant, and as a preservative in mortuaries and medical laboratories. Studies have found that formaldehyde causes myeloid leukaemia and rare cancers.

- Urea-formaldehyde (UF), also known as urea-methanal, is a non-transparent thermosetting resin or polymer. It is produced from urea and formaldehyde. It is used in adhesives, plywood, particleboard, medium-density fibreboard, and moulded objects. Health effects occur when UF-based materials and products release formaldehyde into the air.

- Melamine-urea-formaldehyde (MUF) is a resin that is more resistant to humid environments than UF resins. However, melamine is much more expensive than urea. The MUF resins are used for scarf-jointing of plywood and end-jointing of structural lumber that can be used in protected exterior exposure.

- Phenol-formaldehyde (PF) (phenolic resins or phenoplasts) are synthetic polymers used in many industries because of their strength, versatility, and stability. In the woodworking industry, it is employed as a binding agent between wood laminates. Also, because it is a thermal insulator, PF can withstand high temperatures. PF contains formaldehyde. Phenol can cause damage to the skin and should not be inhaled due to its toxicity.

- Phenol-resorcinol-formaldehyde (resorcinol glue) is an adhesive combination of resin and hardener that withstands long-term water immersion and is highly resistant to ultraviolet light. The adhesive, introduced in 1943, has been popular in aircraft and boat construction. Currently, it is mainly used in plywood, laminated support beams, and other wooden structural elements. Resorcinol can be toxic when inhaled, irritating the nose, throat, and lungs. It also causes skin and eye burns. Repeated exposure may harm the nervous system as well as the kidneys and liver.

- Volatile organic compounds (VOCs) are emitted as gases from certain solids or liquids. VOCs include a variety of chemicals, some of which may have short- and long-term adverse health effects. Concentrations of VOCs are consistently higher indoors (up to ten times) than outdoors. Examples of emitters include paints and lacquers, paint strippers, building materials, and furnishings.

The research conducted at Vares Architecture Residency was funded by the European Union. Its continuation is funded by the Lithuanian Council for Culture.

AISTĖ GAIDILIONYTĖ is an architect and artist interested in activist and other alternative ways of practising architecture. Together with Kamilė Vasiliauskaitė, they explore the material, social and poetic layers of space.

KAMILĖ VASILIAUSKAITĖ is an architect, artist, and researcher from Vilnius. Together with Aistė Gaidilionytė, they explore the material, social and poetic layers of space.

ILLUSTRATIONS: Aistė Gaidilionytė and Kamilė Vasiliauskaitė

PUBLISHED: MAJA 4-2024 (118) with main topic AIR

1 See: Dirk van Weelden ‘The Particleboard Odyssey’, MCGuffin magazine, Issue No. 12 ‘The Log’, May 2023.

2 IKEA, ‘The wood we use’.

3 VMG Group website.

4 See: Duncan Roberts, ‘Frustrated Sanem residents call for halt to Kronospan expansion’, Luxembourg Times, 2 August 2024.