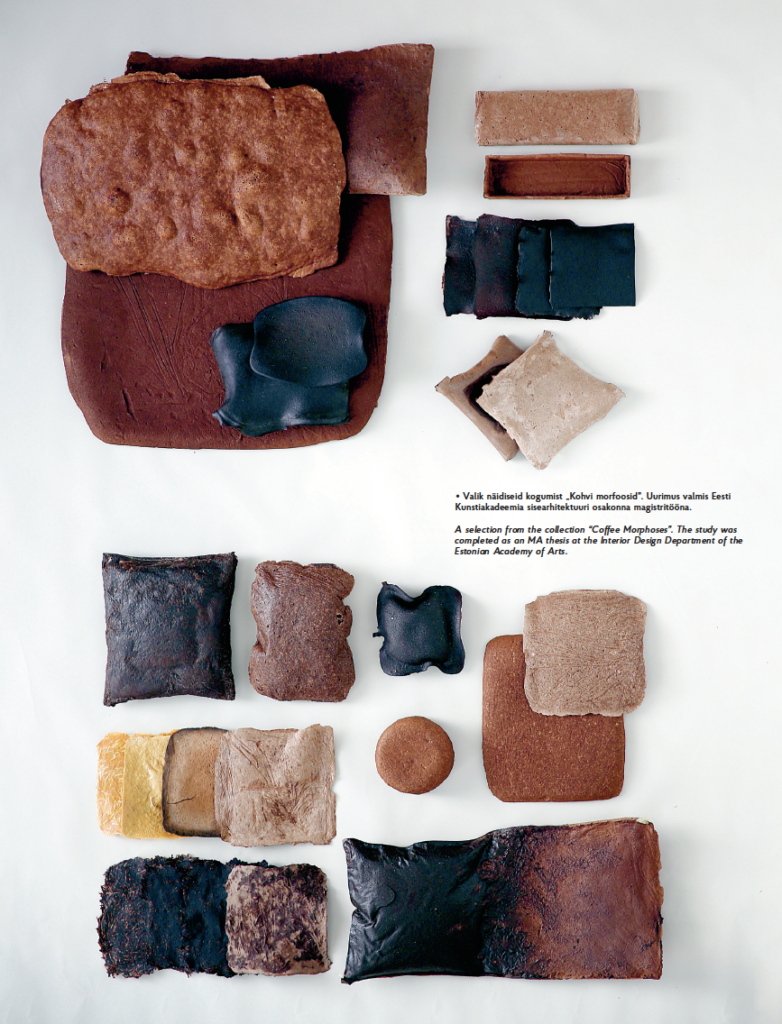

“Coffee Morphoses” is a set of natural materials generated in the course of a practical study. This kind of material manifestation is usually made by designers and architects through experimentation, using their self-invented techniques and processes and may be called authorial materials. In most cases, the idea and generation of material is based on a specific raw material and the author’s personal convictions. By analysing the local organic resource, I came to ask if the waste of imported goods could become the new local raw material.

Coffee is one of the tropical luxury goods that takes years and thousands of miles to reach its consumer. In terms of quantity, about 9 million tonnes of coffee is consumed annually all over the world. Only a fraction of the roasted and ground bean is dissolved in the drink leaving about 80% of primarily cellulose mass as waste.

Materials of various properties were created by means of biopolymers – collagen glues, cellulose derivative, agar, starches etc – used to bind the coffee waste. In addition to the ingredients, the properties of the material were further defined by the drying method and finishing. For instance, the use of freeze-drying (lyophilisation) allowed me to generate structures of various levels of porosity and tactile surfaces. When dried in air, materials were stronger in structure while the final form was mostly deformed. Experiments so far have shown that mixtures can be used to create thinner sheet material, membranes and panels of a few centimetres in thickness as well as surface coating. Suitable tools for manufacturinginclude wood processing equipment while also 3D printing has been tested. The specific features of the material allow its ample usage in product development, for instance, as acoustic and insulation material as well as smaller meaningful design objects.

The common denominator of coffee materials is their hygroscopy and adaptation to the moisture level of the surroundings. Excessive wetting may be prevented by processing the materials with natural waxes. Each processing increases the object’s life span, however, in contrast to high-tech materials, the given self-produced materials are not meant to last forever. Instead, they will last only as long as there is an emotional and caring relationship between the object and the user of the space.

PUBLISHED in Maja’s 2018 spring edition (No 93).