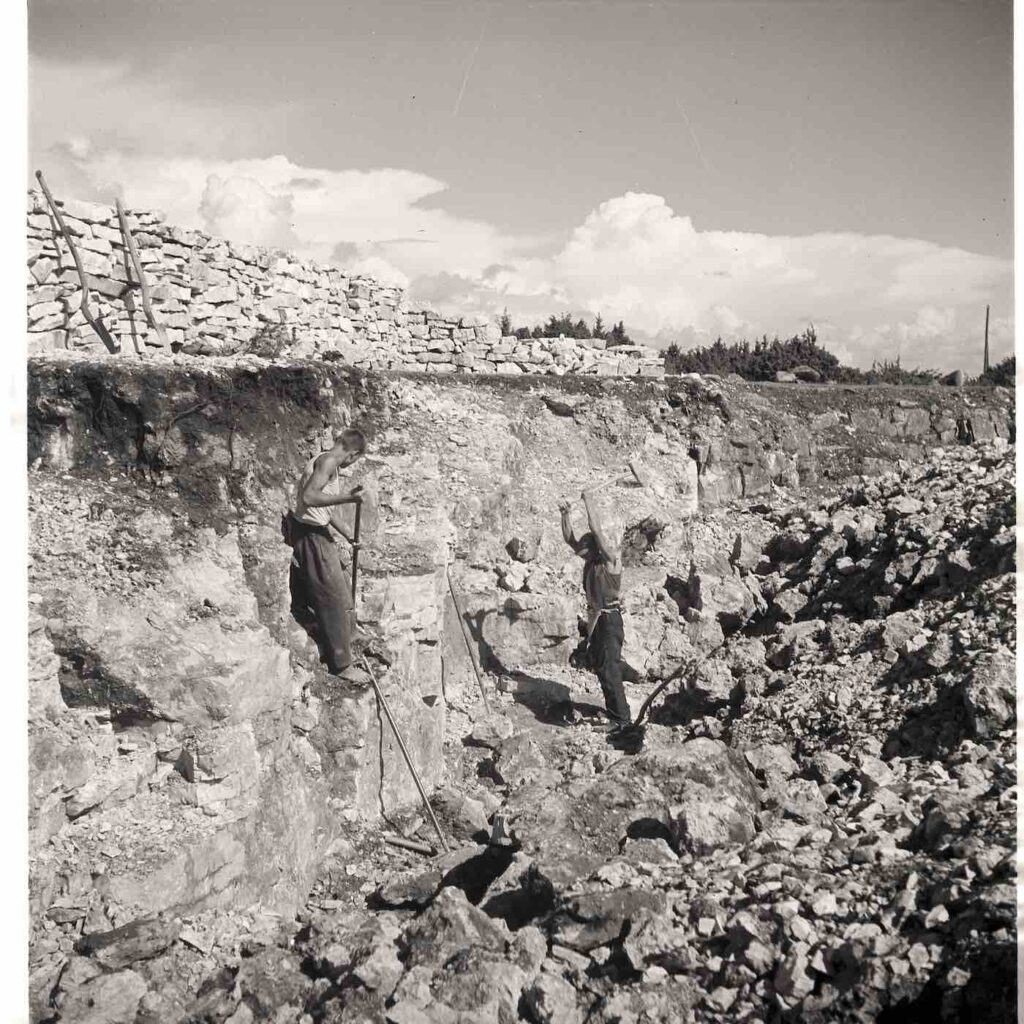

When a certain building technology or material is sidelined for an extended period, one is bound to get the impression that it is intrinsically obsolete. This has happened with natural stone, which architects, when asked about its potential for use, describe only as being too expensive, too labour-intensive, incompatible with the public procurement system and, as can be witnessed in renovation projects, simply too complicated to build with. The inability to imagine a future different from the present is typical to the 21st century, and hence, the main use of limestone in Estonia remains blasting it into rubble that can be utilised as landfill and concrete aggregate.

There are some who think differently. ‘Stone is a new material in our technological context,’ argues English structural engineer Steve Webb in his polemical essay ‘Stone age: a new architecture from an old material’, published in the Architectural Review in 2022. Since the 19th century, research and development in the field of concrete and steel, as well as the curricula of engineers and architects, have completely banished stone from construction, and created a biased conception of building materials.1 In the age of fossil fuels, the euphoric triumph of the aforementioned new materials was a logical outcome—cheap, seemingly endless energy enabled, and still enables, to replace time-consuming masonry work and the expertise involved with a simpler and faster concrete and steel construction. Paradoxically, now that visible catastrophic consequences let us perceive such volumes of energy use as exploitation of our planet, energy has instead become a reason for rediscovering stone.

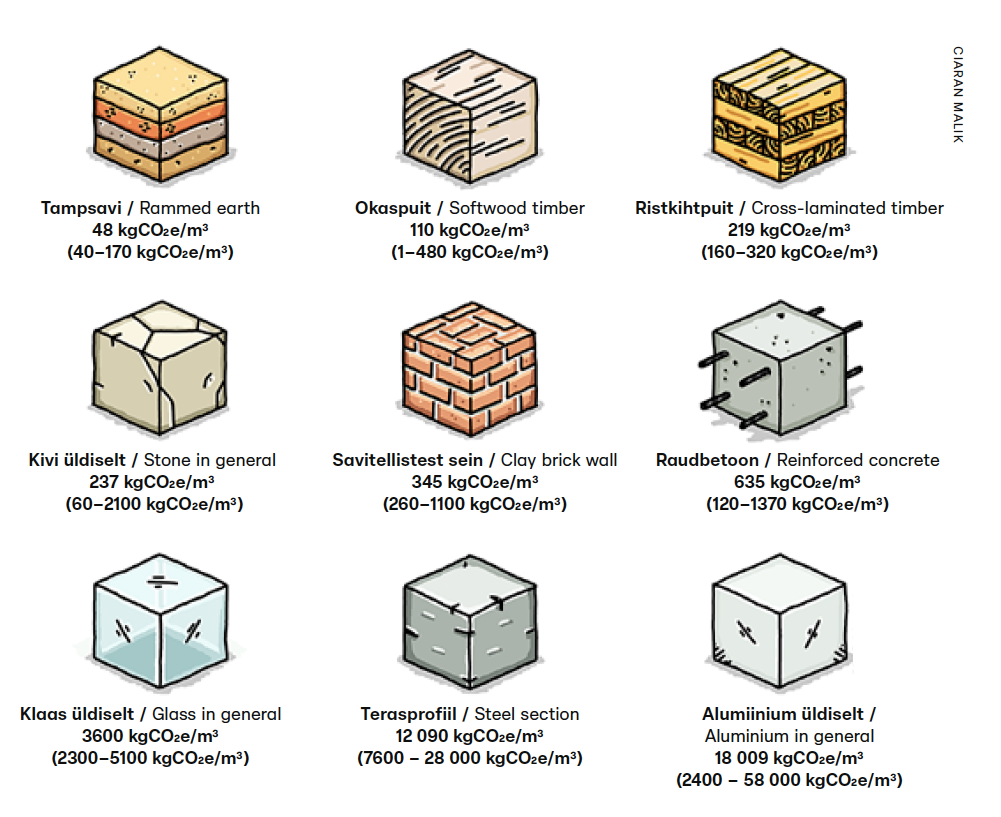

Source: www.circularecology.com/embodied-energy-and-carbon-footprint-database.html

There is one obvious, Excel-compatible reason why use of stone is back on the agenda—as a building material, stone is low in embodied carbon. Given the direction towards stricter CO2 regulations in the construction industry, we can hope that instead of virgin materials with high levels of embodied carbon, we will turn to readily available, renewable and reusable materials that do not require much processing. The amount of embodied carbon in a stone product that is ready for use in construction is about the same as in CLT (in CLT, it is 219 kgCO2e/m3 ; in stone, 237 kgCO2e/m3; in reinforced concrete, 635 kgCO2e/m3 and in steel, 12 090 kgCO2e/m3).2 After it has been quarried, stone does not require much processing, although how much it needs depends on transportation distances, designer’s knowledge as well as aesthetic choices, not to mention the craftsmanship of the builder. Stone has a longer life span than CLT, and is needed in smaller quantities as it is stronger. This does not mean that one should replace the other—they can be used together efficiently and this is indeed what we should do.

Photo: Leo Fabrizio

Stone is not a biomaterial—it is not continuously generated by biological processes. But there is a lot of it—or, as Steve Webb claims, it is inexhaustible. He explains that if we were to build a 25 m2 house out of 200 mm thick stone slabs for every human being in the world, it would leave behind a single 40 km2 wide and 20 m deep quarry—a large hole, however a mere pinprick in global terms.1 Stone that is suitable for use in construction can be found everywhere in the world, although at different depths, and its composition and hence its constructional properties vary. Masterpieces of Gothic architecture such as the cathedrals of Sainte-Chapelle and Saint-Denis near Paris, or Sir Christopher Wren’s later masterpiece, the St Paul’s Cathedral in London, were erected precisely in such geological regions where there are thick layers of uniform, dense limestone that is easy to build with. The plea that has emerged in recent years to expand the scope of stone as a low-carbon construction material is gaining traction mainly in the very same regions of West Europe. Pre- and post-tensioned stone beams have been developed in England, and social housing with stone structure have been built in France and Switzerland. Stone advocates in England point to the capacity for hybrid structures as the main trend for the future, with an emphasis on the synergy of wood and stone. Steel also plays an important role in pre- and post-tensioned structures, but occurs in much smaller quantities than in reinforced concrete structures.

Photo: Chris Jackson

Photo: Agnese Sanvito

Four types of building stone can be found in the territory of Estonia—granite, sandstone, carbonate rock, which includes both limestone and dolomite, and erratics. In actuality, only carbonate rock and erratics can be used in construction, for granite lies too deep, and sandstone lies in the nature reserves of South Estonia. In North Estonia, carbonate rock is often exposed, meaning that extraction can be carried out in quarries rather than underground mines. Lots of know-how, skills as well as quarries have been preserved in Estonia, but use of stone has nevertheless been relegated to luxury and renovation projects. Could there be a greater role for local stone? Types of limestone that are widespread all across North Estonia include some high-quality building stone. This is demonstrated by the crucial, literally load-bearing role that limestone and dolomite play in numerous still-preserved medieval buildings as well as the early 20th-century industrial architecture in Tallinn.

The formation period of stone hundreds of millions years ago is difficult to fathom, but nevertheless significant. Carbonate rock has sedimented in layers of varying thickness, tonality and other properties. Estonian geologist Helle Perens, who has thoroughly studied the use of carbonate rock in Estonian buildings, emphasises that our local carbonate rock is at least twice as old as the famous Portland stone in England, the building material for St Paul’s Cathedral. This means that the layers of carbonate rock here are thinner and have more cracks, requiring different technical solutions from those typical in West Europe. The limestone in Estonia is 5–22 cm thick, depending on the layer and depth; the length and width of an uninterrupted layer could be up to 5 metres. We also have dolomite—e.g., in Inju, Lääne-Viru County—which has a more uniform composition and comes in thicker layers, thus enabling to build with larger blocks.

This has enabled the stairs of Inju manor house, built in 1894, to withstand more than a hundred years of usage and weather. The weather resistance of carbonate rock depends on the bed from which it is quarried. Certain less-porous beds that are responsive to freezing cycles are suitable to be used in exterior conditions and load-bearing structures, whereas other, softer and more layered beds can be used in interior conditions, withstanding the level of usage typical there.

Stone entrepreneur Hillar Müür says that interest in the use of limestone has been growing slowly but steadily in Estonia since the 1990s, although use remains limited to mainly tilework—except in renovation projects, where it is used also in load-bearing structures. In the recent years, limestone has reappeared in façades, since it withstands the local climate well and requires little maintenance. In a façade, however, it usually occurs in the form of thin panels, which, after having been glued to the wall, are no longer reusable in the future. Slicing a block of stone that has an immense load-bearing capacity into thin slabs brings it immediately to the final stage of its possible uses.

Given its potential, carbonate rock is underutilised in Estonia. Both Helle Perens and Hillar Müür underscore that local stone is currently used in a reckless way—rock beds with good properties suitable for quarrying building stone are instead used to produce crushed stone. For instance, 800 metres from Hillar Müür’s quarry in Maardu, which produces building stone from Lasnamäe limestone, there is another quarry that produces crushed stone from the very same rock. This kind of downgrading of stone is also highlighted by Steve Webb, who exemplifies it with an account of stone with a compressive strength of 100–250 MPa being ground, then fired, then mixed with sand brought from the other side of the world and clean water, just to produce a material with a compressive strength of 40 MPa—i.e., concrete—which still needs to be supplemented with significant amounts of steel before it could be used in structural parts.3

It would be unimaginative to think that there are no new ways for using stone—that with the 21st century we have exhausted our palette of building materials, since certain materials do not fit into the current public procurement system. We should draw inspiration from Steve Webb’s plea—the technological context surrounding us today is so radically different from the one in the beginning of 20th century when stone was last used more widely that natural stone qua building material should be approached with fresh eyes, without shying away from radically rethinking the uses of this historic material. But who would take up the task of initiating that new approach and carry the risks that are involved? Adoption of such ‘new’ technologies as building with stone or soil is mainly hindered by the current lack of scalable work processes and local examples. Entrepreneurs who feel comfortable in the construction sector today are not interested in developing it. Trying something new would be less risky, of course, if one first invests in research and prototyping. The fact that there can be innovative ways of using seemingly traditional building materials is clearly shown by the Estonian timber sector. It is a question of time and capital invested in research and development. What if we directed private and public money not only to studying timber, but also to studying our other important natural resource—carbonate rock?

One weak point of building with stone is alleged to be its characteristic temporal dimension, which does not fit with the current models of construction and design, in which everything is available immediately, regardless of the required amount or time of year. This allegation can be turned on its head by asking whether using natural stone could help us render the current building culture more sustainable. In the Estonian climate, carbonate rock can be quarried approximately from April to December. For the rest of the year, carbonate rock quarries are filled with water due to recurrent freezing and thawing, and the temperature is too low for working there anyway, since the work is carried out in outdoor conditions and mostly by people. This kind of seasonality feels inconvenient in our modern 24/7 demand-and-supply culture, but rests on more sustainable practices of considering the longer-term perspective and planning more carefully. Constant increase in speed and productivity is one of the root causes of our current crises. For an alternative vision of the future, we could see the slowing down of construction processes as a positive phenomenon.

In her doctoral dissertation that studied the modern use of stone in buildings from an ethnographical point of view, architect Natalia Petkova describes a change in design culture that comes with using stone in construction. The deepening compartmentalisation of various parties is characteristic of work organisation in late capitalism, into which factory-based material production fits perfectly, but natural materials with heterogenous properties as well as circular use of building materials and products call for a more intertwined way of doing things. Designer, builder, material producer and supplier are not easily replaceable in case of stone materials, and all the problems that might arise have to be solved through dialogue. Petkova cites an example from Switzerland—in the course of building an apartment building, there was a dispute between the client and contractor, due to which they decided to visit the quarry. This helped all parties to understand the quarrying process and let them collaboratively develop a material supply chain that took everyone’s possibilities into account and thus simplified the construction process.4 Finding and developing new solutions requires a closely interacting team and an understanding of each other’s work. Both in the design stage and on the construction site, various parties need to collaborate rather than arrive and leave as isolated brigades.

With increasing demands for sustainable construction, we should also ask ourselves what kind of employment and work culture are we creating when we create a building. What are the social consequences of building something? Right now, it is indeed cheaper to use coal- and fossil fuel-produced energy to create simplified steel and concrete structures than to hire people to design and build more complex buildings that are more economical in terms of materials.3 In a reversed scenario, in which building materials would be taxed more and people’s work would be taxed less, one can imagine that building and material use would need to be considered more carefully, leaving more space for the mastery of materials and more labour-intensive technologies. More extensive use of stone seems super complicated with the social contract that is in force today, but this only invites one to go beyond technical specifications and think about where the materials are produced and what the production processes are like; who receives and who loses work when something is built; how to support local production of materials with design and procurement decisions; how familiar is the designer with the peculiarities of material production and its effects on the people producing them. Materials are not merely figures in a table or textures on an illustration, but the result of a hundreds, hundreds of thousands, millions of years-long process; production takes place at a particular location and involves work by people.

No building material can solve the problem with the extensive environmental impact of the construction sector. There is no point in dividing materials into good and bad, because in the end, the agency of a material manifests in a larger network—what is built, who builds and for whom, how much is built, how comfortable should it be and how long should it last. Likewise with stone—it might not be the answer, but it could be an opportunity. Perhaps it is time for us to approach stone from a new angle? In the context of modern technologies, natural stone is a wholly new material, low on embodied carbon, locally available and important not only sentimentally, but also as a contributor to the local socioeconomic context. In the second coming of stone architecture, geologist Helle Perens, engineer Steve Webb and architect Natalia Petkova all emphasise the need to learn from historical buildings. We can focus on developing the material and working out new solutions, of course, but we should not ignore the fact that stone has been used in construction for thousands of years, and many very old stone buildings are still standing. We have the opportunity to learn from our low carbon past, without trying to go back in time and recreate what used to be.

LAURA LINSI is an editor-in-chief of MAJA.

MARIA HELENA LUIGA is a founder of kuidas.works and master’s student in architecture at the Royal Danish Academy.

ROLAND REEMAA is an architect, lecturer and founder of LLRRLLRR studio.

HEADER: Natural stone has a greater agency in the design process—including both the design idea and the logic of construction—than man-made materials. This means that the properties of stone itself play a greater role in determining the shape and appearance of the designed building than the properties of steel and concrete. Photo by Timothy Soar

PUBLISHED: Maja 1-2024 (115) with main topic STONE

1 Steve Webb, ‘Stone age: a new architecture from an old material’, The Architectural Review, 06.04.2022.

2 Cíaran Malik, ‘Cradle to Gate Embodied Carbon A1 – A3’, a diagram from the author’s website, which is in turn based on the database ‘Embodied Carbon – The ICE Database’ (2019), circularecology.com

3 Steve Webb, ‘Building with stone’, presentation at the online seminar of Architects Climate Action Network, 11 September 2023.

4 Natalia Petkova, „ETHNOGRAPHY OF STONE. Gathering – Layering – Cementing“, Dimensions. Journal of Architectural Knowledge, vol. 2, no 3 (2022).