Last year I defended my Master’s thesis at the Faculty of Architecture of the Estonian Academy of Arts researching a thoroughly new building material – peat and oil shale ash composite. Both substances in their pure form are poorly applicable or even unusable in construction. Things get interesting, however, as soon as you join the two materials. In addition to architects Martin Melioranski and Renee Puusepp, the thesis was also supervised by materials researcher Jüri Liiv from Tartu University who provided the original idea to combine the given materials.

The cooperation between the schools allowed us to undertake various lab experiments. The compression tests of composite material supervised by Tõnis Teppand at the mechanics lab of the Academy of Life Sciences gave us the result of about 1 MPa with the thermal conductivity test result 0,07 W/mK. The generation of a one-layer structure is hindered by the fact that peat walls need to be protected from rain. This could be achieved by tar finishing or a wood shingle system. There is no need to worry about fire as the mineral substances in the oil shale ash make the composite virtually fireproof.

I was further motivated by a personal recognition that peat is something highly characteristic of Estonia encompassing added value that is difficult to define (already due to its formation process). As a raw material, oil shale ash is an environmental hazard. Its highly alkaline pH level can be neutralised with peat with its naturally acidity. Similarly to carbon sequestration, the chemical reaction between the two materials allows the locking of heavy metals found in the ash. The potassium in oil shale ash makes the humate found in natural peat soluble with the new material providing an ideal environment for growing plants. In order to create a strong construction material, the humates need to be washed with ash water.

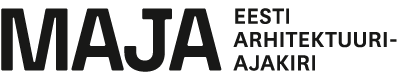

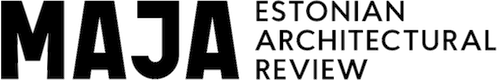

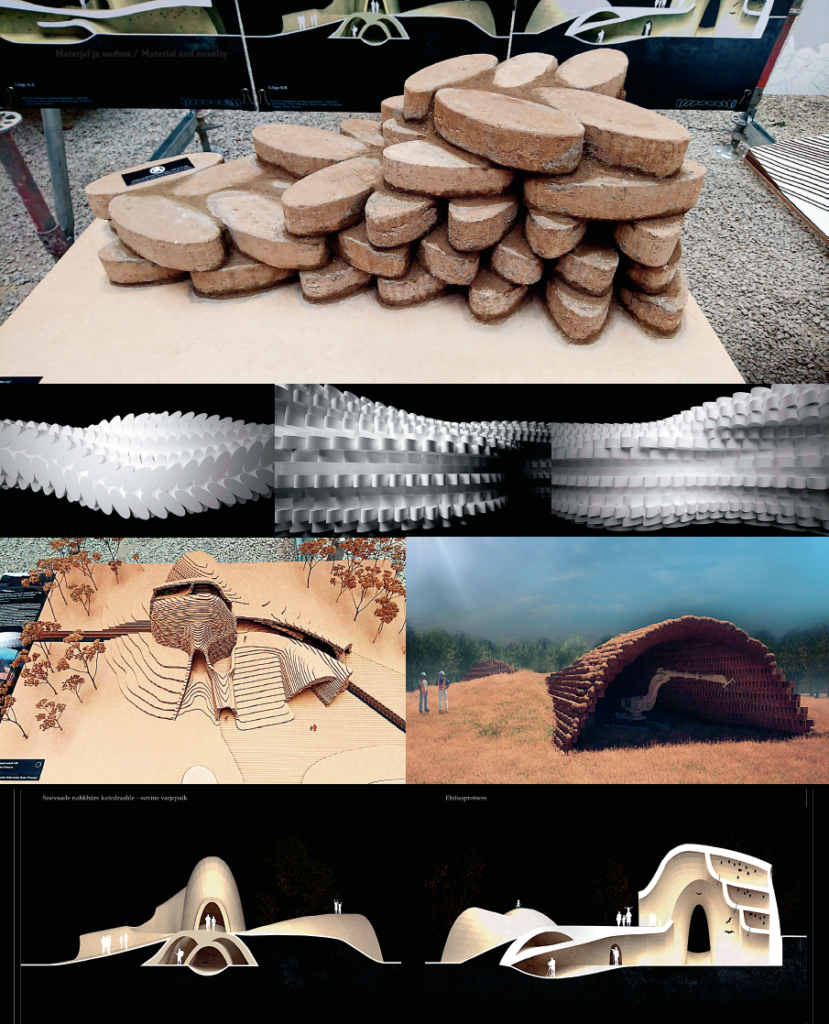

The main part of the Master’s thesis is constituted by the research on how to treat the material and make it stronger. I suggested an anisotropic system of ellips shaped blocks made of natural fibre in which the strength of the wall is controlled with the precise placement of the blocks. I also devised a method of laying vaults with no support structure. All means were implemented in the design of the chiroptorium or bat cave at Tallinn Zoo. Now we can only hope that the development of the highly potential material will be allocated further funding and the construction of peat domes enriching the local building traditions may begin.

Published in Maja’s 2018 spring edition.